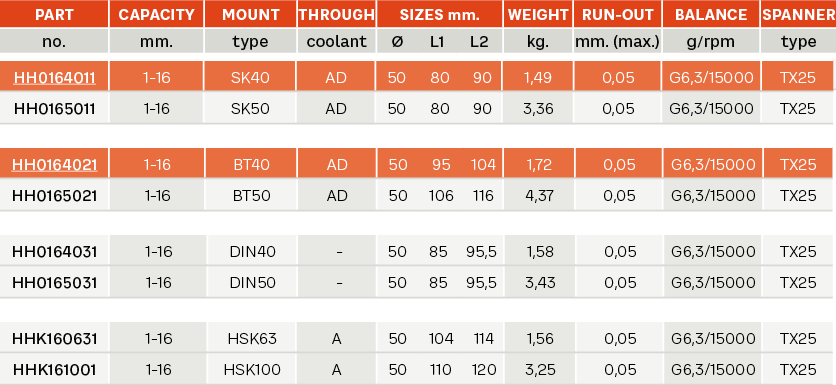

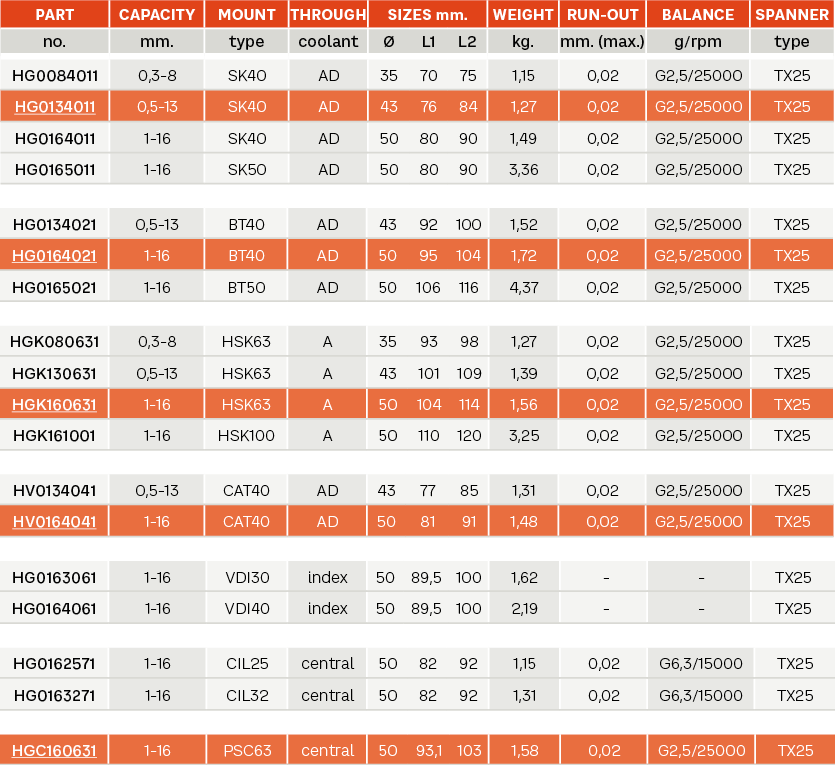

With SLIM CHUCK BODY for optimal accessibility Super Precision Drill Chucks with integrated shank and Torx Key lock

Features Balanced to 15.000 rpm G6,3. Maximum total integrated run-out of 0.05 mm. (.002”). Available in capacity range 1-16 mm only. Available in DIN, BT, ISO and HSK shank types. Tool retention torque up to 50 Nm. With Balluff chip bore. Through coolant form AD. Lateral clamping system with Torx (25) key and worm gear mechanism. Permits clockwise and counterclockwise turning. Drilling, milling and reaming. Maximum coolant pressure: 50 bar. Furnished with instructions for use manual

Unique and innovative design This unique chuck, designed and patented by Llambrich combines the features and benefits of both a keyed and keyless drill chuck.

Specifically designed for high precision drilling. The Hybrid combines the high accuracy of a keyless chuck with the gripping force of a keyed chuck.

Features Self-tightening feature automatically increases gripping force in proportion to the increase of torque to prevent tool slippage. The Hybrid is furnished with a key to allow additional gripping torque. The tool better resists loosening on high speed machines that have instant spindle stop 0,04 mm (.0016”) repeatability on taper mounted chucks. Llambrich, the leader in precision. The Hybrid series is well suited for use on drill presses with high accuracy, jigbore machines, horizontal or vertical milling machines, and production drilling machines where the application requires higher feed rates. Special designs, sizes, and mounts for all types of applications are available upon request.

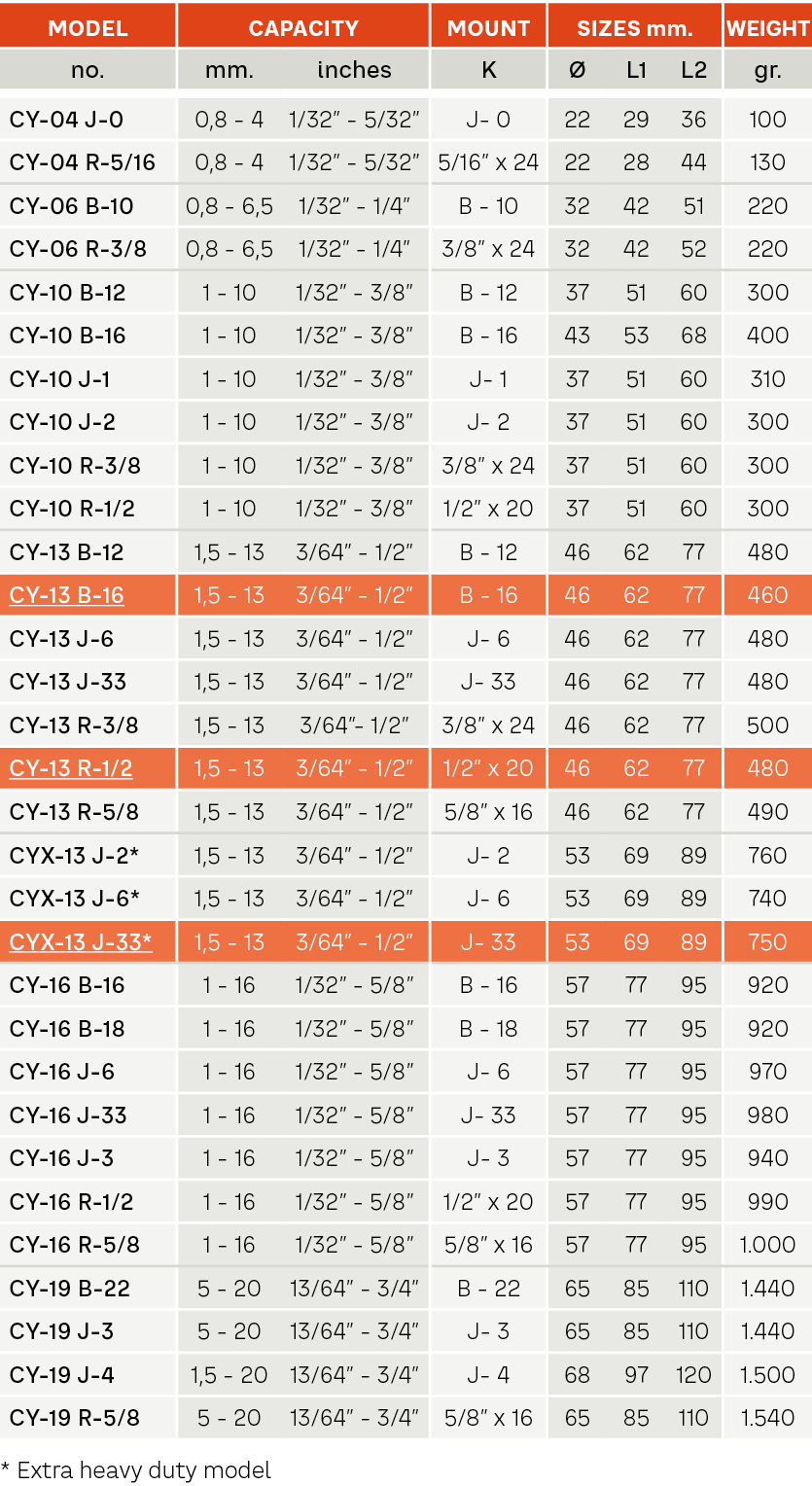

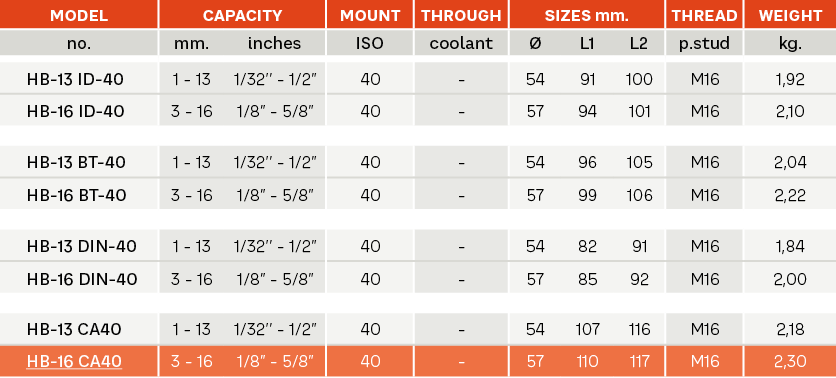

INDUSTRIAL Drill Chucks with key for stationary machines and portable drilling machines

Features Specially designed for stationary drilling, turning, milling and wood working machines. The one-piece gear ring and sleeve eliminate the possibility of tooth breakage. The jaws, gear ring and body are all totally hardened to avoid wear and lengthen the life of the drill chuck. Fits tools of up to 20 mm in diameter. (3/4”). Machine fitting via DIN-238 or JACOBS tapers and UNF screw fittings. Wide range of accessories.

BALL-BEARING Drill Chucks with key for production drilling equipment

Features Drill chuck with key for industrial applications that require the toughest machining conditions. Equipped with ball bearings to reduce friction in the tightening mechanism and provide a better grip on the drill shaft. All the pieces are hardened and ground. The one-piece gear ring and sleeve eliminate the possibility of tooth breakage. Fits tools of up to 25 mm. (1”), machine fitting via Jacobs tapers.

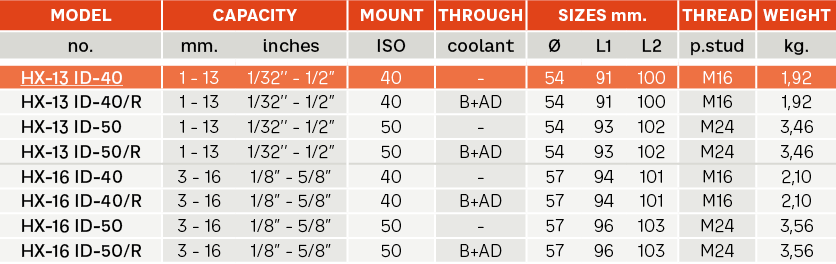

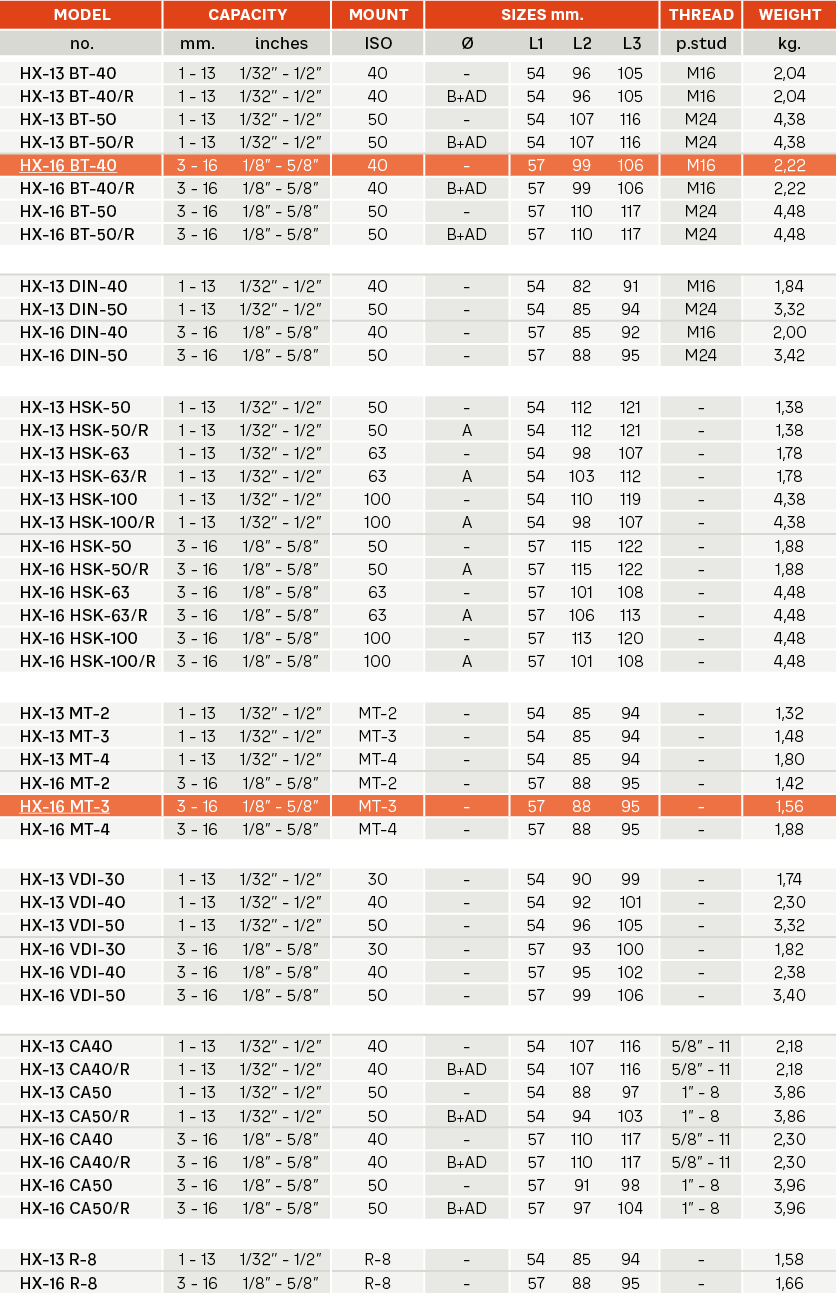

Precision drill chucks with integrated shank and Hexagonal Key lock

Features For use on high-speed CNC machines, optional through coolant for drilling, milling and reaming. Hexagonal key lock system. Permits clockwise and counterclockwise turning. Maximum tightening torque 20 Nm. Maximum total integrated run-out of 0,03 mm (.0012”). Maximum coolant pressure: 50 bar. Maximum revolutions per minute without balancing: 8.000. Optional balancing service up to 25.000 rpm G2.5.

Great quality at a fair price Standard drill chucks with integrated shank and Hexagonal Key lock

Features For use on CNC machines, for drilling, milling and reaming. Hexagonal key lock system. Permits clockwise and counterclockwise rotating. Maximum tightening torque 20 Nm. Maximum total integrated run-out of 0,05 mm. (.0019”). Maximum revolutions per minute without balancing: 8.000.

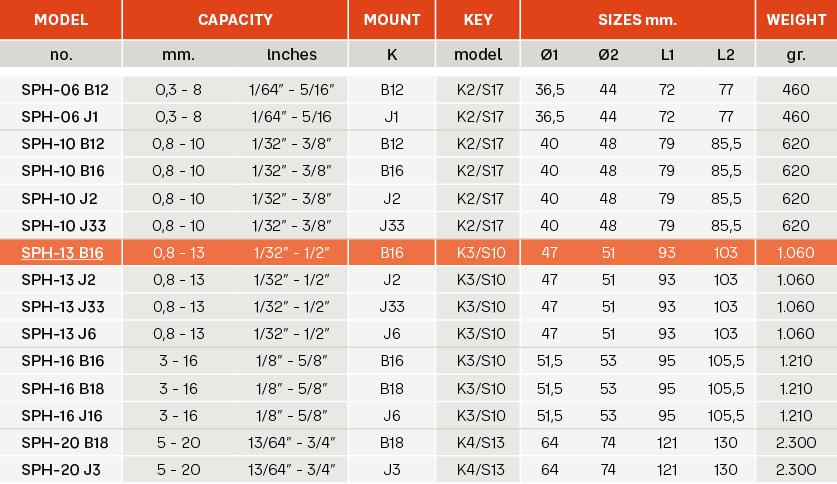

With SLIM CHUCK BODY for optimal accessibility. Super Precision Drill Chucks with integrated shank and Torx Key lock.

Features Balanced to 25.000 rpm G2,5. Maximum total integrated run-out of 0.02 mm. (.0008”). Available in capacity ranges 0,3-8 - 0,5-13 - 1-16 mm. Available in DIN, BT, CAT, HSK, VDI, STRAIGHT & CAPTO shank types. Tool retention torque up to 50 Nm. With Balluff chip bore. Through coolant form AD. Lateral clamping system with Torx (25) key and worm gear mechanism. Permits clockwise and counterclockwise turning. Drilling, milling and reaming. Maximum coolant pressure: 50 bar. Furnished with instructions for use manual.